Technical

What we use

Lenzing Fire Retardant

Lenzing Lyocel for workwear

Lenzing Fire Retardant

Botanic origin

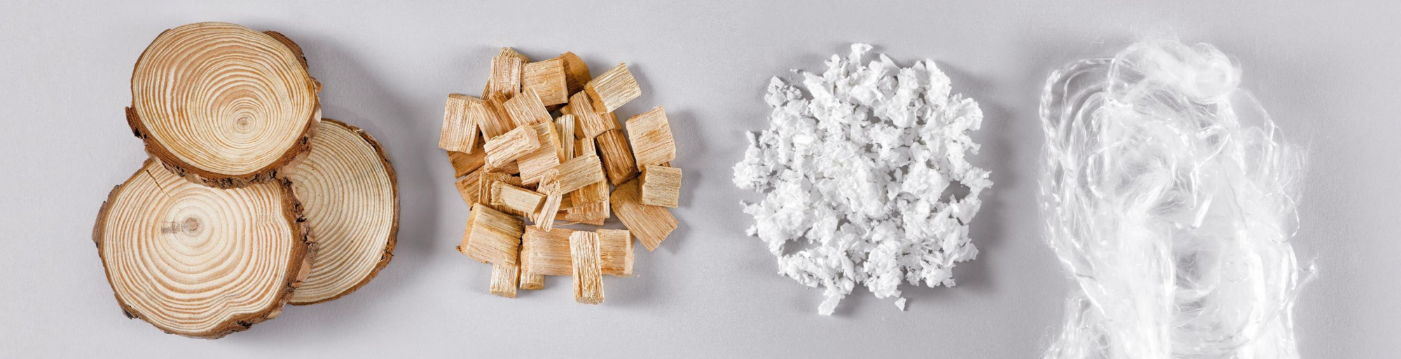

LENZING™ FR® fibers are inherently flame-resistant cellulose fibers produced using the Modal fiber production process. LENZING™ FR® fibers are mainly manufactured from beech wood, sourced from sustainably grown forests in Austria and neighboring contries. Beech wood forests are a natural and renewable source of raw material. A big share of the wood used at the Lenzing site comes from Austria, harvested from certified or controlled sources following the stringent guidelines of the Lenzing Wood and Pulp Policy. LENZING™ FR® fibers have earned United States Department of Agriculture (USDA) BioPreferred.

Forest

Wood

Pulp

Fiber

Yarn

Fabric

End product

Sustainable production

Fully intergrated pulp and fiber production at the Lenzing site in Austria makes it possible to produce LENZING™ FR fibers in an eco-responsible way. At Lenzing, we strive to safeguard resources for future generations by the use of renewable energy from the pulp mill and by the recovery of remaining components as co-products.

Numerous Lenzing innovations have been intergrated in the production of LENZING™ FR fibers provide efficient ecological advantages substituting

for the resource-intensive conventional dyeing process. This brings significant life cycle savings of water and energy from cradle to finished fabric; for example up to 50% of energy and water savings as well as a 60% reduced carbon footprint, resulting in a much lower environmental impact compared to conventionally dyed fabrics.

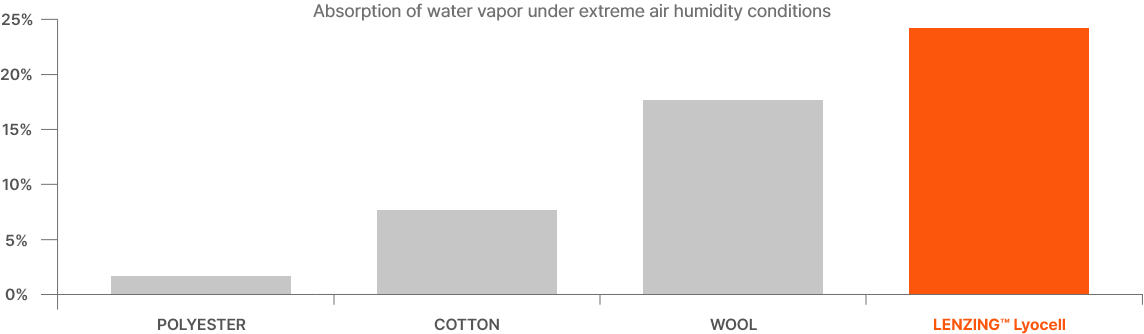

Enhanced breathability

Fabrics made from LENZING™ FR fibers support body temperature regulating properties through their moisture management. Drived from natural material, the microscopic fibrils of cellulosic fibers are structured to regulate the absorprion and release of moisture, contributing to fabric brethability that supports the body’s natural thermal regulation. LENZING™ FR cellulose fibers have a higher vapor uptake than cotton.

Color retention (LENZING™ FR fibers & Eco Color technology)

Fully intergrated pulp and fiber production at the Lenzing site in Austria makes it possible to produce LENZING™ FR fibers in an eco-responsible way. At Lenzing, we strive to safeguard resources for future generations by the use of renewable energy from the pulp mill and by the recovery of remaining components as co-products.

LENZING™ FR® fiber production process

Lenzing Lyocel for workwear

LENZING™ FR® fiber production process

- Derived from the natural resource wood. Various sustainably managed tree species, such as spruce, pine, birch, beech and eucalyptus are used.

- The wood is harvested only from certified and controlled sources, protecting ancient and endangered forests, evident by:

- FSC® certification (FSC-C041246)

- PEFC™ certification (PEFC/06-33-92)

- Recognized with “Dark-Green Shirt” – the best ranking in Hot Button Report from Canopy Style Initiative.

LENZING™ fibers produced from the raw material wood

- LENZING™ for Workwear cellulosic fibers contribute to clothing fabrics offering natural comfort in a wide variety of working environments

- Their botanic origin, environmentally responsible production process, and biodegradability reflect Lenzing’s commitment to sustainability, while their unique physical properties cater to the diverse needs of different occupations.

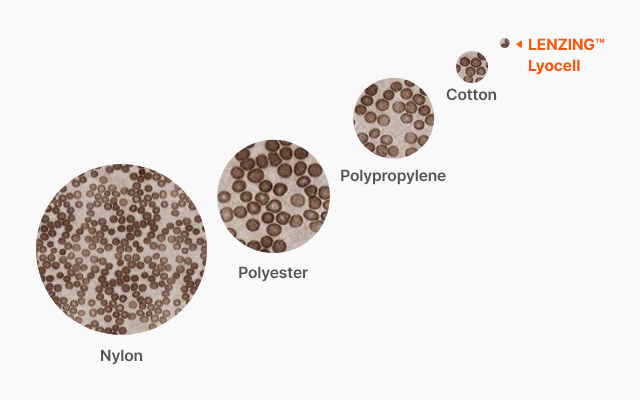

LENZING™ Lyocell fibers absorb large amount of water vapor

LENZING™ Lyocell fibers demonstrate the highest moisture absorption

Feature

Better hygienic qualities

LENZING™ Lyocell fibers provide a less favorable environment for bacterial growth offering better hygienic qualities

Feel cool and dry

Better hygienic qualities

LENZING™ Lyocell

Offers functional key benefits for Workwear application

Enhanced breathability

Gentle on skin

Thermal regulation

Drape

Unfavorable for bacterial growth

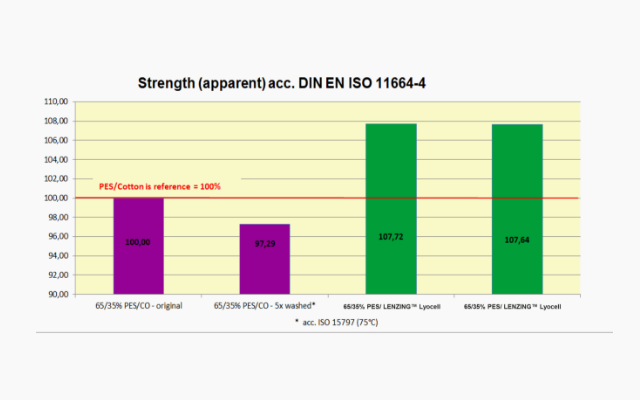

Strength

Smoothness

Minimal static charge

Contribute to performance

LENZING™ Lyocell fibers absorb large amount of water vapor

Corporate Uniform

Private Uniform

Hospital and Industrial

Office Uniform

Police Uniform